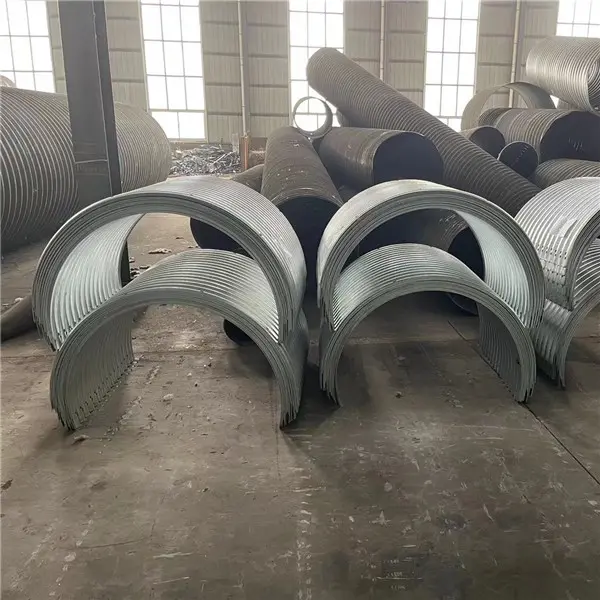

They are commonly used for culverts, stormwater management, drainage systems, and other applications where strength and longevity are crucial. In this article, we will explore the different sizes of corrugated steel pipes, their specifications, and a general price guide to help you choose the right CSP for your project.

Corrugated Steel Pipe Sizes and Specifications

Corrugated steel pipes come in various diameters, thicknesses, and lengths to suit different project requirements. The most common sizes range from small diameters of 6 inches to large diameters of up to 144 inches or more. Here’s a detailed breakdown of the standard sizes and their specifications:

1. Diameter

Small Diameter CSP: 6 inches (150 mm) to 24 inches (600 mm)

Medium Diameter CSP: 30 inches (750 mm) to 72 inches (1800 mm)

Large Diameter CSP: 78 inches (1950 mm) to 144 inches (3600 mm) or larger

2. Corrugation Profiles

Corrugation profiles refer to the pattern of ridges and grooves on the pipe, which provide structural strength. Common corrugation profiles include:

2 2/3” x 1/2” (68 mm x 13 mm): Suitable for smaller pipes and light-duty applications.

3” x 1” (76 mm x 25 mm): Standard for most medium-sized pipes.

5” x 1” (125 mm x 25 mm): Used for larger pipes that require additional strength.

9” x 2.5” (229 mm x 64 mm): For extra-large pipes used in heavy-duty applications.

3. Thickness

The wall thickness of corrugated steel pipes is measured in gauge. The thickness you choose depends on the load-bearing requirements of your project. Common gauges include:

16 Gauge (1.52 mm): Light-duty applications.

14 Gauge (1.91 mm): Standard for most medium-duty applications.

12 Gauge (2.66 mm): Heavy-duty applications.

10 Gauge (3.51 mm): Extra heavy-duty applications, such as culverts under highways.

4. Lengths

CSP is typically available in standard lengths of 20 feet (6 meters) or 24 feet (7.3 meters), but custom lengths can be manufactured based on project requirements.

5. Coating and Lining Options

To enhance durability and resist corrosion, CSP can be coated or lined with various materials:

Galvanized Steel: Standard zinc coating for moderate corrosion resistance.

Aluminized Type 2: Offers better corrosion resistance than galvanized.

Polymer Coating: Provides superior protection against corrosion and abrasion.

Asphalt Lining: Improves hydraulic performance and resistance to corrosion.

Corrugated Steel Pipe Sizes Chart

Here’s a table showcasing the typical sizes of corrugated steel pipes along with their specifications:

| Diameter (inches) | Diameter (mm) | Corrugation Profile | Thickness (Gauge) | Standard Length (feet) |

|---|---|---|---|---|

| 6 | 150 | 2 2/3" x 1/2" | 16 | 20, 24 |

| 12 | 300 | 2 2/3" x 1/2" | 14 | 20, 24 |

| 18 | 450 | 3" x 1" | 14 | 20, 24 |

| 24 | 600 | 3" x 1" | 12 | 20, 24 |

| 36 | 900 | 5" x 1" | 12 | 20, 24 |

| 48 | 1200 | 5" x 1" | 10 | 20, 24 |

| 60 | 1500 | 5" x 1" | 10 | 20, 24 |

| 72 | 1800 | 9" x 2.5" | 10 | 20, 24 |

Corrugated Steel Pipe Price Guide

The price of corrugated steel pipes varies based on size, thickness, coating, and other factors. Below is a general price guide:

1. Small Diameter CSP (6” to 24”):

Galvanized: $10 to $20 per linear foot

Aluminized: $15 to $25 per linear foot

Polymer Coated: $20 to $30 per linear foot

2. Medium Diameter CSP (30” to 72”):

Galvanized: $25 to $50 per linear foot

Aluminized: $30 to $60 per linear foot

Polymer Coated: $35 to $70 per linear foot

3. Large Diameter CSP (78” and above):

Galvanized: $50 to $100+ per linear foot

Aluminized: $60 to $120+ per linear foot

Polymer Coated: $70 to $140+ per linear foot

Factors Affecting CSP Pricing:

Material Costs: Steel prices fluctuate, impacting the overall cost of CSP.

Coating and Lining: Additional coatings, such as polymer or asphalt lining, increase the cost.

Transportation: Shipping large-diameter pipes can be expensive due to their size and weight.

Custom Sizes: Non-standard sizes or lengths may result in higher costs due to special manufacturing processes.

Choosing the Right Corrugated Steel Pipe

When selecting a corrugated steel pipe for your project, consider the following:

Load Requirements: Determine the weight and pressure the pipe will need to withstand.

Environmental Conditions: Consider the potential for corrosion, abrasion, and exposure to chemicals.

Hydraulic Needs: Choose a size and lining that provide the necessary flow capacity.

Budget: Balance the specifications with your project budget to find the best solution.

Conclusion

Corrugated steel pipes are versatile and durable solutions for many infrastructure projects. Understanding the various sizes, specifications, and pricing will help you make an informed decision for your next project. Whether you need a small diameter pipe for drainage or a large diameter pipe for a culvert, there is a CSP option that meets your requirements. Always consult with a trusted supplier to ensure you choose the right corrugated steel pipe for your specific needs.