January 22, the provincial government held a provincial science and technology awards in Jinan, in recognition of the province science and technology innovation and modernization have made outstanding contributions to science and technology workers. Shandong Kenda by Professor Zhou Xuejun and Tongji University Professor Li Guoqiang and other completed and Shandong built the first complete unit declared much scientific and technological achievements "lightweight steel web of twists and turns the key technology and engineering," Shandong Province Science and Technology Progress Award, Fuzhuan Guo, Vice President, Science and Technology Department and the award on behalf of responsible comrades attended the ceremony.

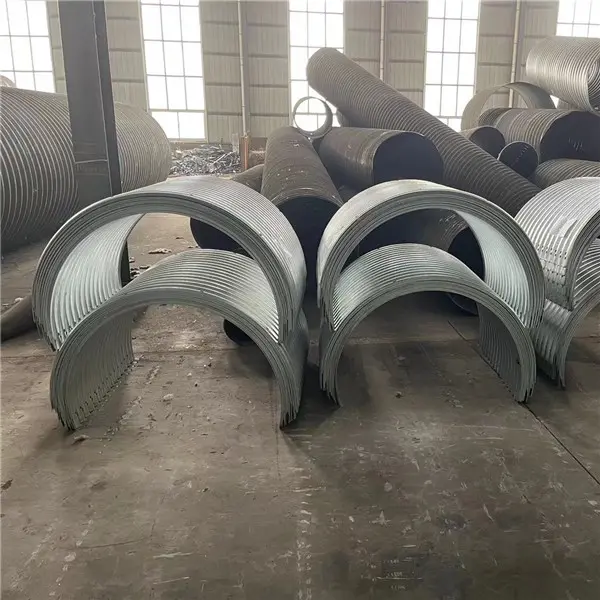

The project will form a web of twists and turns corrugated web, greatly improve the stability of the steel web, the web thickness is reduced by more than 50%, to achieve light weight and materials. The outcome of the establishment of a complete corrugated web steel design theory. Addresses this new steel web and flange locally stable beam overall stability and local pressure, fatigue, a combination of a series of calculation and design of beams and other theoretical issues, the preparation of the first specialized domestic and foreign design specifications; developed corrugated steel webs proprietary manufacturing equipment. Forming webs solve key technical problems member welding residual stress and deformation control, long-lasting protection, etc., developed a thick corrugated web (t> 8mm) not contain molded, thin corrugated web (2mm) H-beam automatic welding, anchor hook composite corrosion, 360-degree spin welding stress relief and other key manufacturing equipment; the formation of a corrugated steel web system connection and installation processes. Proposed to adapt the web geometry irregular corrugated web steel connection joint construction and design methods, the formation of a corrugated web steel system installation process and specialized installation process for the high section of corrugated steel webs large span buildings and bridges . H-beam automatic welding, anchor hook composite corrosion, 360-degree spin welding stress relief and other key manufacturing equipment; forming a corrugated steel web system connection and installation processes. Proposed to adapt the web geometry irregular corrugated web steel connection joint construction and design methods, the formation of a corrugated web steel system installation process and specialized installation process for the high section of corrugated steel webs large span buildings and bridges .

The project is eligible for 31 patents (including patents 11), published 25 research papers design theory. Preparation of national industry standard "composite bridge with corrugated steel webs" JT / T784-2010 and "corrugated web steel technical specification" CECS291: 2011, to fill our web steel products and design technology standard blank. Built the country's first with independent intellectual property rights of corrugated web steel components of automated production lines, breaking the monopoly of the technology and equipment developed countries, the successful development of 2800 tons molding equipment not contain, as the current world's largest non-containment thick corrugated webs molding equipment.

The project has been applied in more than 100 major projects Yantai tide airport, Jingjiang sports centers, has achieved remarkable economic and social benefits, and promote the construction of technological progress, leading the technical innovation of the steel structure engineering and materials conservation .